Product control

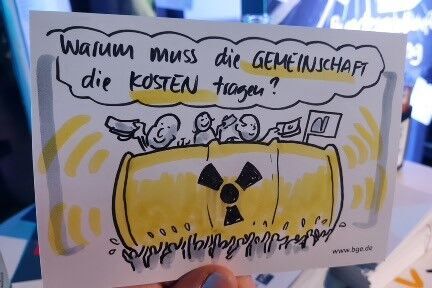

- Radioactive waste must be packaged in approved containers for final disposal.

- In addition, the filled containers must be checked and monitored.

- All production and inspection protocols must be kept.

To ensure safety, the loaded containers undergo a variety of examination procedures prior to final disposal. Here, a combination of checking the conditioning (packaging suitable for final disposal) and spot checks has proven to be effective. This product control includes a check of whether the waste is packaged according to the applicable final disposal conditions. Responsibility for the control procedure lies with the Bundesgesellschaft für Endlagerung (BGE). Independent expert bodies then check the containers on the BGE’s behalf.

Product control of the waste containers can be carried out in two different ways – either by applying a packaging procedure certified by the BGE or through spot checks of already-packaged waste containers.

Qualified procedure for conditioning

The principles underlying the conditioning specifications stem directly from the Atomic Energy Act and the Radiation Protection Ordinance. In principle, before applying a procedure for the treatment and packaging of radioactive waste, the applicant must demonstrate that the resulting waste products meet the requirements of the final disposal conditions, which are a key part of a repository’s license. The process itself is accompanied by independent expert bodies. This ensures that the waste is treated and packaged in a manner suitable for final disposal and that everything is documented in accordance with the regulations.

Spot checks of existing containers

The information provided by the waste producer in relation to the radioactive waste is randomly verified by means of independent analyses. This procedure is primarily intended for so-called old waste, whose conditioning was not subject to accompanying checks by independent expert bodies.

Non-destructive techniques are used to examine the containers from the outside without damaging them. For example, this can be achieved by means of dose rate measurements at the container surface, computed tomography, or the analysis of gas samples.

Other methods result in damage to the container. For example, it is possible to drill into a container in order to obtain a core for further analyses.

Tasks of the expert bodies

The expert bodies commissioned within the framework of product control must have the necessary expert knowledge for their task and be independent. Among other things, they check the presented descriptions of waste products and packaging, the conditioning technique, the containers used, and the composition of the waste inside the container. Finally, experts from the BGE check whether the statements from the expert bodies are complete and correct and meet the specifications of the planning approval.

Product control explained in 90 secounds (english subtitle)

By calling up the video, you agree that your data will be transmitted to YouTube.

Only approved and checked containers may be used for final disposal

The finished containers must undergo further checks prior to final disposal

© KTE Karlsruhe